Injection Molded Cases

An injection molded case is created by a manufacturing process known as injection blow molding. Injection blow molding is performed in a specialized plastic manufacturing facility using advanced equipment to shape the materials into the dimensions of the case. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

As one of the Midwest’s oldest plastic molders, Koller-Craft has craftsmanship built into its name. We take pride in our quality injection molding work. Large to small parts, short to long runs. Excelling at product design, prototyping, close tolerance molding, insert molding & secondary services.

Performance Engineered Products, Inc. is a dynamic and innovative company, and we pride ourselves on being at the forefront of the injection molded plastics industry. With a rich history dating back to 1981, we have consistently demonstrated our commitment to excellence in both products and services.

We may have started small, but today, we offer our products and services to companies around the world. We are dedicated to our customers, and our goal is to offer better service and pricing to any customer no matter the size.

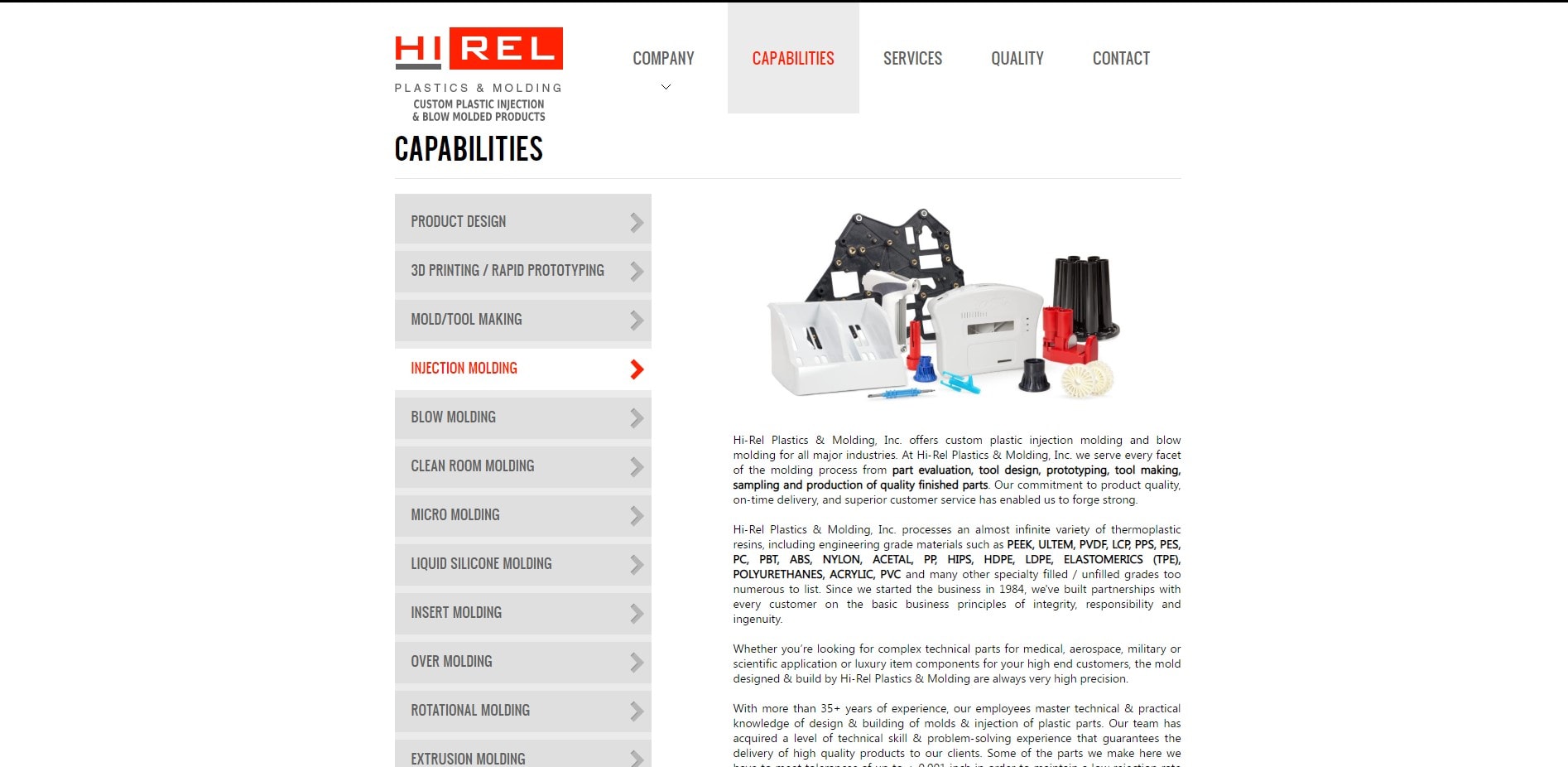

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

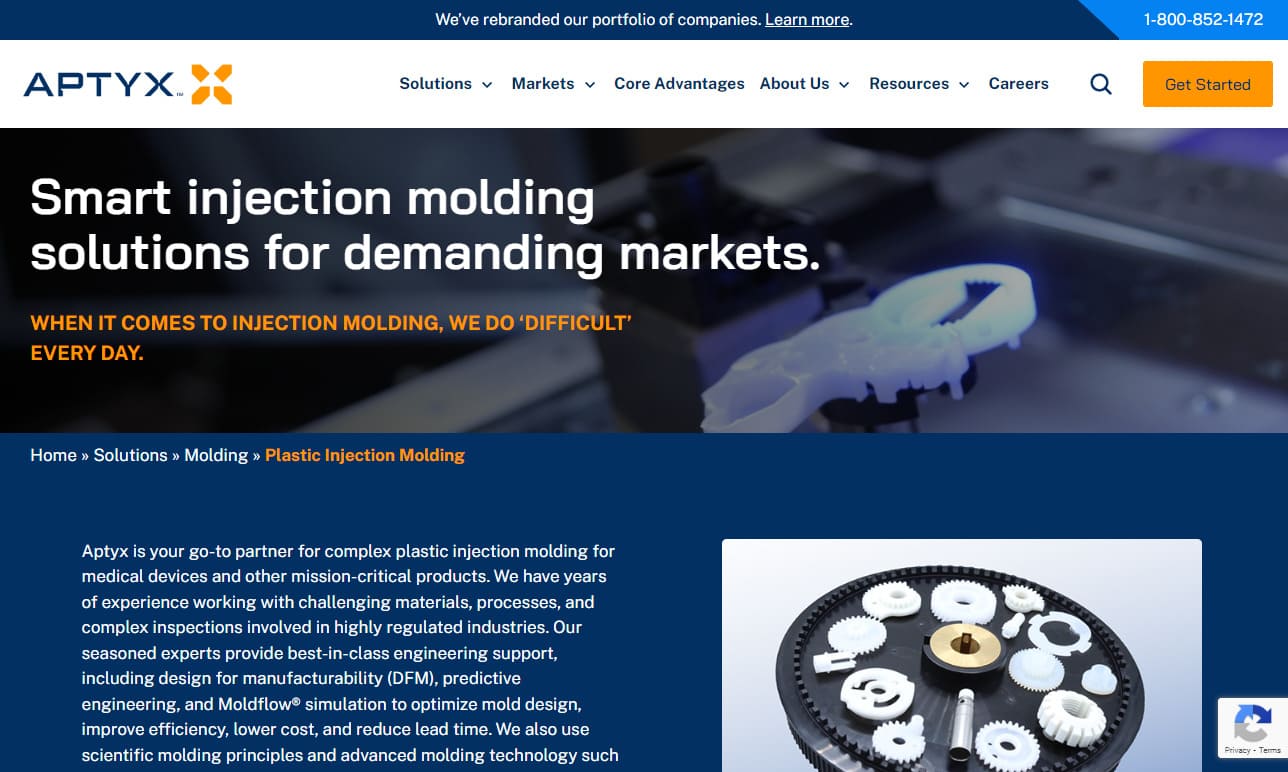

A leader in the plastic processing industry for over 70 years, Aptyx provides a range of manufacturing services including injection, blow and dip molding, extrusion, and assembly. Within injection molding we are deeply experienced in complex processes such as over molding, two-shot molding and insert molding. With a focus on delivering high-quality product and exceptional customer service, you...

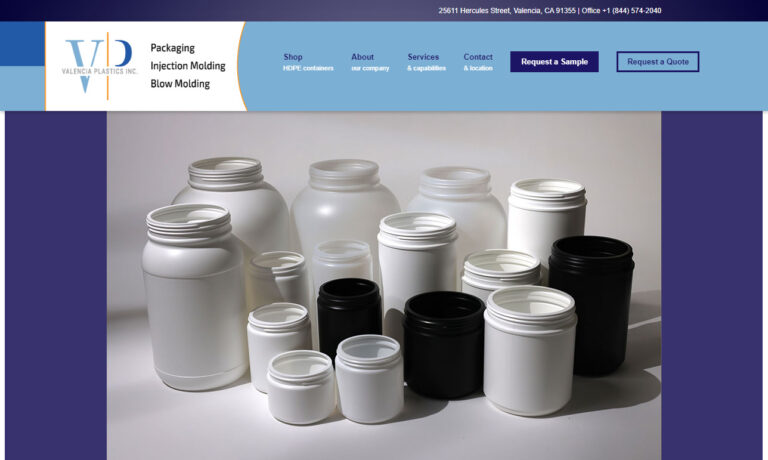

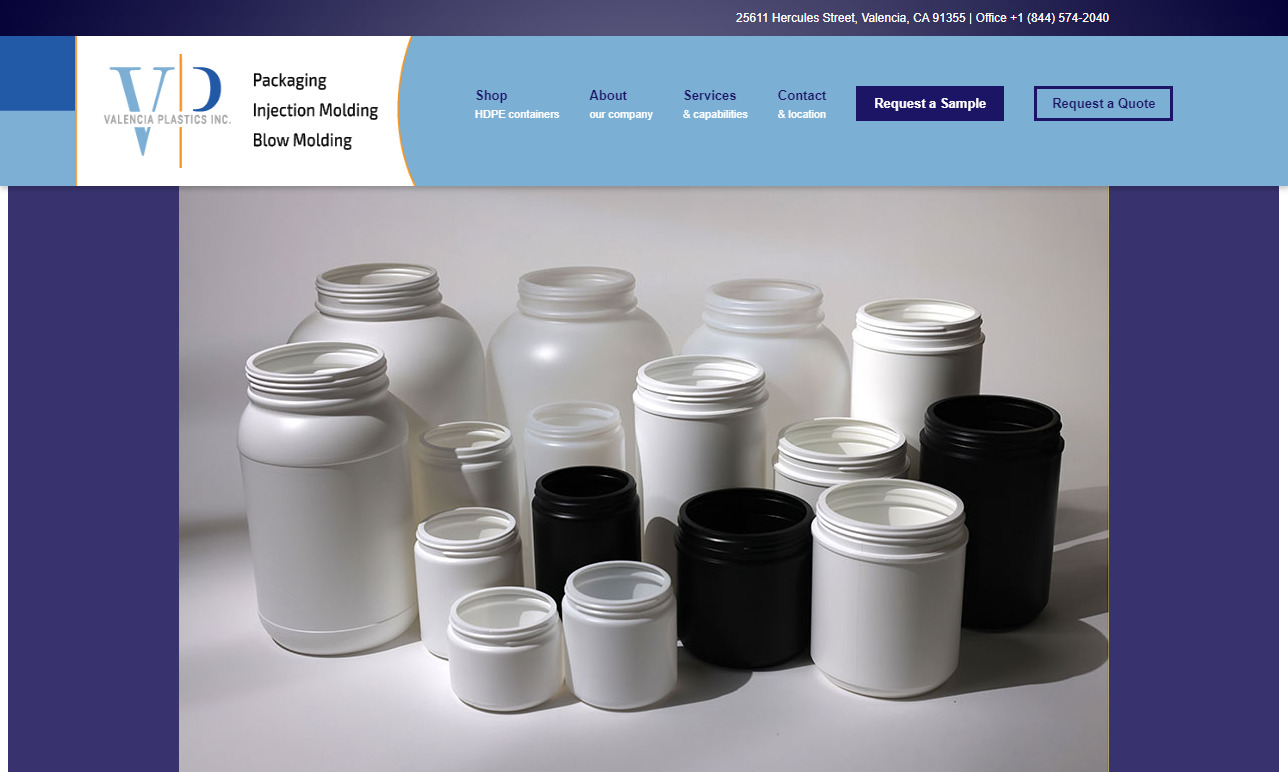

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

More Injection Molded Case Companies

The plastic material that will be used for the case (usually polyethylene) is first melted down and then injected onto a core pin. As this core pin rotates over a molding station the material is inflated with air so that a hollow area is created in the middle. The plastic is then given time to cool. Once it has cooled down, the plastic is removed from the mold and it remains formed to the exact shape of the case mold. The same mold can be used over and over again to create a case with the exact same specifications.

Injection molding is an ideal manufacturing process for large volume runs in a major manufacturing facility where hundreds or even thousands of injection molded cases may be manufactured at the same time. This is because once the mold has been designed and the equipment has been programmed, the injection molding process itself is very quick and easy to repeat.

Injection molded cases are made in many different shapes and sizes depending on the types of objects that they are made to hold. They may be used for electronic devices, sound equipment, heavy tools, instruments or a wide array of other goods that a person would want to protect from damage. Most cases are built with clasps to keep them tightly sealed, and some even have a built-in key lock beside the carrying handle for added security.

If the case is designed to accommodate a very specific item, the mold may be setup in such a way that the hollow portion on the inside of the case is in the exact shape of that item. This way, when the item is placed inside it will not shift when the case is moved. Sometimes an inner foam lining is cut in the shape of the object and added to the case after it has been molded.

A high quality injection molded case has many advantages besides basic damage protection. These cases are waterproof, lightweight, immune to rust, impact resistant and scratch resistant. Specialized trades personnel can use these cases to carry their equipment without having to worry about it being damaged by an accident on a busy job site.

Injection molded cases are used in applications that range from military to engineering to healthcare and beyond. The durability of their structure and the infinite design possibilities that the molding process allows for makes them a great choice for almost any industry. A rugged design, cost-efficient means of production and high degree of customization make injection molded cases a highly sought after product around the world.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services