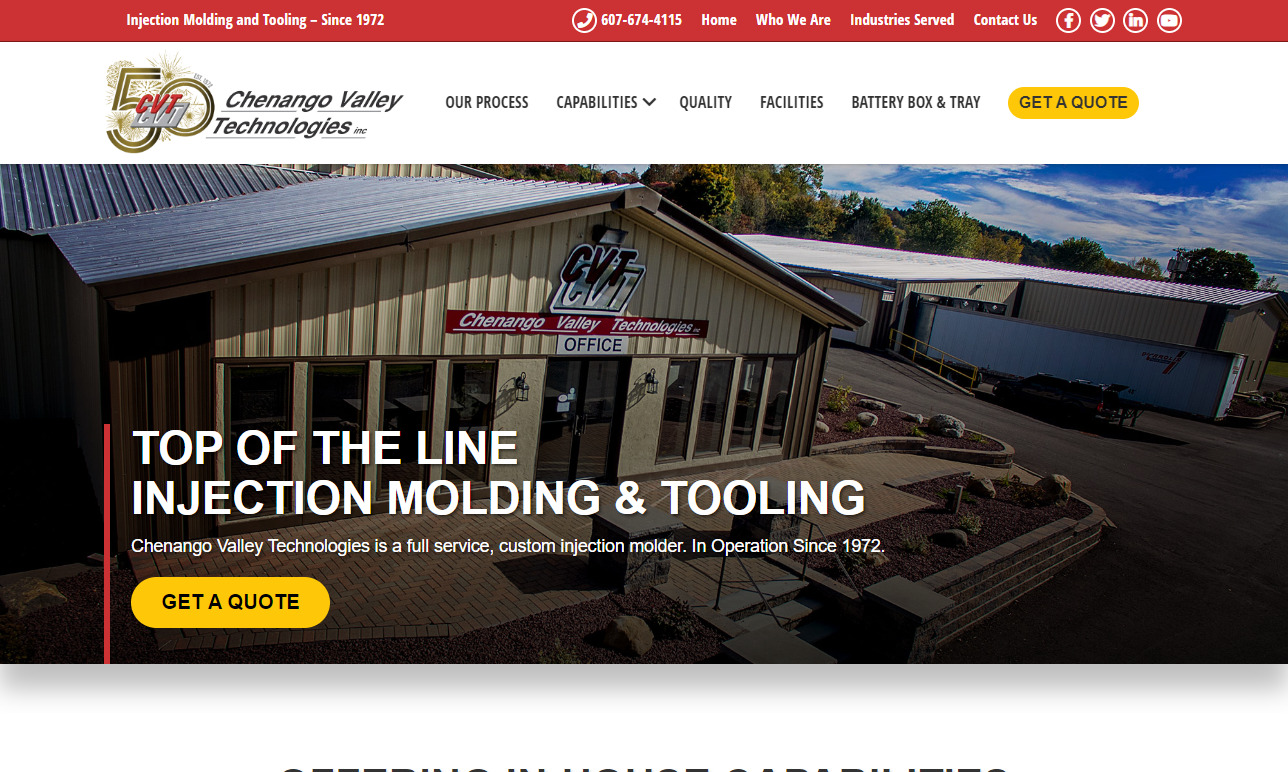

Chenango Valley Technologies Inc.

Chenango Valley Technologies Inc.Request A Quote

Sherburne, NY | 607-674-4115https://www.chenangovalleytech.com/

Chenango Valley Technologies Inc., located in Sherburne, NY, is a reputable provider of Injection Molded Plastics products and services. With a strong commitment to innovation, quality, and customer satisfaction, we specialize in delivering high-performance plastic components for various industries and applications. Our state-of-the-art facilities, experienced team, and dedication to excellence make us a trusted partner for our customers. Products: At Chenango Valley Technologies Inc., we offer a wide range of Injection Molded Plastics products designed to meet diverse industry needs. Our product portfolio includes: 1. Custom Injection Molded Parts: We have extensive expertise in manufacturing custom injection molded plastic parts tailored to our customers' specifications. Our team of skilled engineers collaborates closely with clients to understand their unique requirements and design precise and reliable components. Whether it's intricate small parts or larger complex assemblies, we have the capabilities to produce high-quality components in a variety of shapes, sizes, and materials. 2. Automotive Components: We supply injection molded plastic components for the automotive industry. Our components are used in various automotive applications, including interior and exterior parts, lighting, electrical systems, and more. We understand the stringent requirements of the automotive sector, and our components are designed to meet the industry's standards for durability, reliability, and aesthetics. 3. Consumer and Industrial Products: Chenango Valley Technologies Inc. manufactures injection molded plastic components for consumer and industrial applications. Our products are used in appliances, electronics, power tools, sporting goods, and other consumer and industrial goods. We prioritize functionality, quality, and cost-effectiveness, ensuring that our components meet the specific needs of each application. Service Capabilities: In addition to our comprehensive product offerings, we provide a range of service capabilities to support our customers throughout the manufacturing process. Our service offerings include: 1. Design and Engineering Support: Our skilled design and engineering team collaborates closely with customers to develop and optimize product designs for injection molding. Using advanced software and simulation tools, we ensure that the designs are manufacturable, cost-effective, and meet the desired performance requirements. 2. Prototyping and Testing: We offer rapid prototyping services to help customers validate and refine their product designs. Through 3D printing and CNC machining, we can quickly produce functional prototypes for form, fit, and functional testing. We work closely with customers to ensure that their designs meet their expectations before proceeding to full-scale production. 3. Tooling and Mold Making: Chenango Valley Technologies Inc. has expertise in tooling and mold making. We have a dedicated team of skilled toolmakers who utilize advanced technologies and precision machining to manufacture high-quality molds. Our molds are designed for durability, accuracy, and efficient production processes, ensuring consistent and reliable component production. 4. Injection Molding Production: With our state-of-the-art injection molding machines and experienced operators, we offer reliable and efficient injection molding production services. We have the capacity to handle both small and large production volumes, ensuring flexibility and responsiveness to our customers' needs. Our manufacturing processes are closely monitored to maintain consistent quality and meet delivery timelines. 5. Quality Assurance: Quality is a top priority at Chenango Valley Technologies Inc. We have stringent quality control measures in place to ensure the reliability and performance of our Injection Molded Plastics products. Our dedicated quality assurance team conducts thorough inspections, tests, and measurements throughout the production process, adhering to industry standards and customer specifications. Industries Served: Chenango Valley Technologies Inc. serves a wide range of industries, including automotive, electronics, consumer goods, and more. Our Injection Molded Plastics products are trusted for their quality, precision, and reliability. We are committed to building long-lasting partnerships with our customers, providing tailored solutions that meet their specific industry requirements.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services