Armstrong Mold Corporation

Armstrong Mold CorporationRequest A Quote

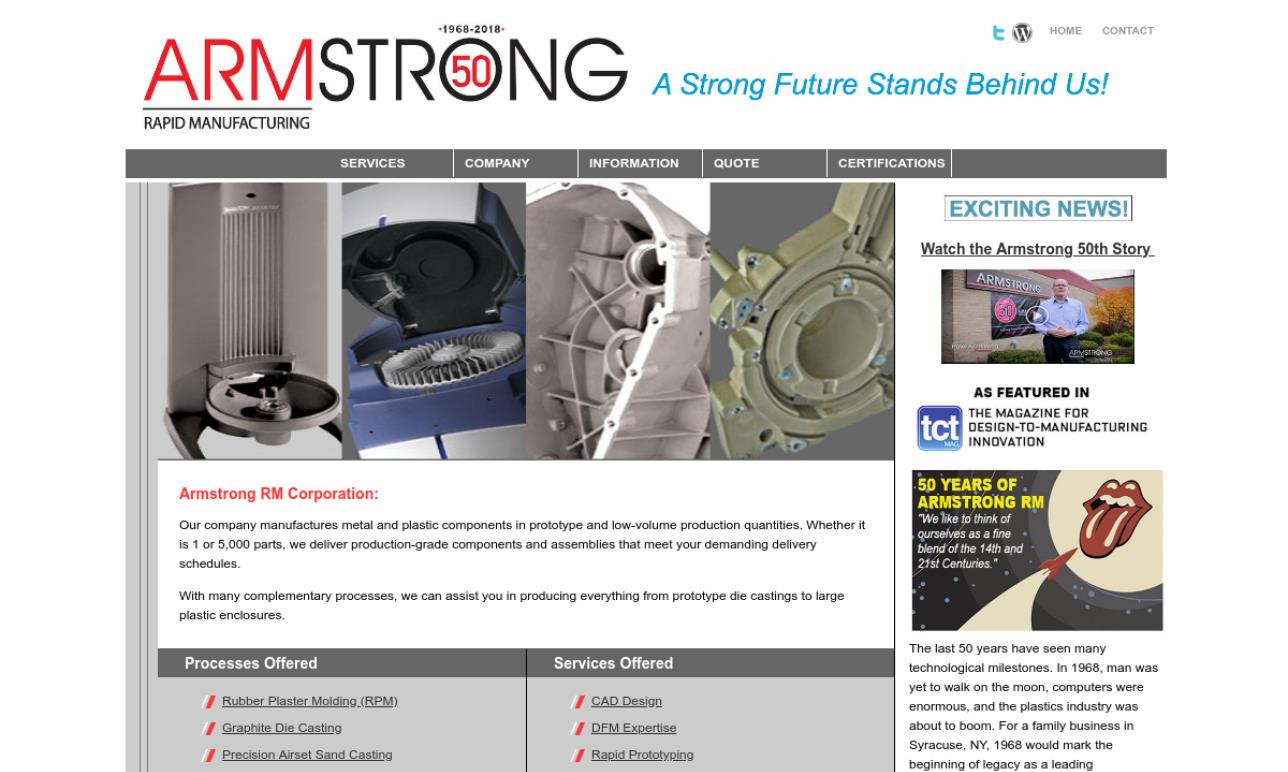

East Syracuse, NY | 315-437-1517Armstrong Mold Corporation, located in East Syracuse, NY, is a leading provider of Injection Molded Plastics products and services. With over 40 years of experience in the industry, we have established ourselves as a trusted partner for plastic molding solutions. Our commitment to quality, innovation, and customer satisfaction sets us apart in the market. Products: Armstrong Mold Corporation offers a diverse range of Injection Molded Plastics products to meet the needs of various industries. Our product portfolio includes: 1. Custom Injection Molded Parts: We specialize in manufacturing custom injection molded plastic parts tailored to our clients' specifications. From small intricate components to large structural parts, we have the capabilities to produce high-quality plastic parts with precision and consistency. Our team of experienced engineers and technicians collaborates closely with customers to ensure the design, functionality, and performance of the molded parts meet their specific requirements. 2. Industrial Components: We produce a wide range of injection molded plastic components for industrial applications. Our industrial components include housings, enclosures, brackets, fittings, and other parts used in equipment, machinery, and systems. We prioritize durability, strength, and resistance to various environmental factors to ensure our industrial components perform reliably in demanding conditions. 3. Consumer Products: Armstrong Mold Corporation manufactures injection molded plastic products for the consumer goods industry. Our consumer products include packaging solutions, household items, electronic device accessories, and other plastic components used in various consumer applications. We focus on aesthetics, functionality, and durability to create consumer products that meet the demands of the market. Service Capabilities: In addition to our extensive product offerings, Armstrong Mold Corporation provides comprehensive service capabilities to support our customers throughout the product development and manufacturing process. Our service offerings include: 1. Design and Engineering Support: Our team of skilled designers and engineers collaborates with customers from the initial concept stage to optimize the design for injection molding. We utilize advanced design software and simulation tools to ensure manufacturability, cost-effectiveness, and optimal performance of the final product. 2. Prototyping and Testing: We offer rapid prototyping services to help customers validate their product designs before full-scale production. Our prototyping capabilities, including 3D printing and prototype tooling, allow for quick turnaround times and iterative design improvements. We also conduct thorough testing and analysis to ensure the functionality, durability, and performance of the prototypes. 3. Tooling and Mold Making: Armstrong Mold Corporation has extensive expertise in tooling and mold making. We utilize advanced CNC machining and EDM technologies to create high-quality molds with precise tolerances. Our skilled toolmakers and mold designers ensure the molds are robust, efficient, and capable of delivering consistent and repeatable results. 4. Injection Molding: Our facility is equipped with state-of-the-art injection molding machines that can handle a wide range of part sizes and complexities. We employ various molding techniques, including multi-cavity molding, insert molding, and overmolding, to accommodate diverse customer needs. Our experienced technicians monitor the molding process closely to ensure product quality and adherence to specifications. 5. Secondary Operations: Armstrong Mold Corporation provides a range of secondary operations to enhance the functionality and appearance of injection molded parts. These operations include assembly, machining, welding, printing, and surface finishing. We can also assist with packaging and logistics, ensuring a seamless transition from manufacturing to delivery. Industries Served: Armstrong Mold Corporation serves a broad range of industries, including automotive, aerospace, electronics, medical, consumer goods, and more. Our Injection Molded Plastics products are trusted for their quality, precision, and reliability. With our commitment to innovation, advanced manufacturing capabilities, and customer-centric approach, Armstrong Mold Corporation is a preferred partner for plastic molding solutions.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services