An injection molded case is created by a manufacturing process known as injection blow molding. Injection blow molding is performed in a specialized plastic manufacturing facility using advanced equipment to shape the materials into the dimensions of the case. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

Quality Plastics, LLC. has become a premier leader in the injection molded plastics industry through our hard work and dedication. Out injection molding capabilities allow us to manufacture sizes from 55-1300 tons. Quality Plastics, LLC. is your trusted manufacturer for all injection molded plastics needs.

At TMF Plastic Solutions, precision and quality define our approach to injection molding. Advanced manufacturing capabilities and a deep understanding of material properties allow us to produce durable, high-performance plastic components for a variety of industries.

At Central Plastics, we’ve built our reputation on being the dependable partner that customers can count on—experienced, approachable, and always responsive. As a custom molder rooted in the heart of California, we specialize in high-quality injection molded plastics and thermoformed packaging.

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

At EXI-plast Custom Moulding Ltd., we specialize in delivering high-quality injection molding solutions tailored to our client's diverse needs. With years of experience and advanced manufacturing capabilities, we excel in producing precision-molded components for various industries. Partner with us for reliable and customized injection molding solutions.

At Zauderer Associates, Inc., we specialize in providing high-quality injection molding solutions tailored to meet the diverse requirements of our clients. Our team leverages extensive experience and advanced technology to produce precision-molded components that consistently exceed expectations.

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

At Nanoplas, Inc., we specialize in mold maintenance products for the plastic injection mold industry. With decades of experience and a commitment to innovation, we work closely with clients across industries to enhance the performance, reliability, and efficiency of injection molding operations.

More Injection Molded Case Companies

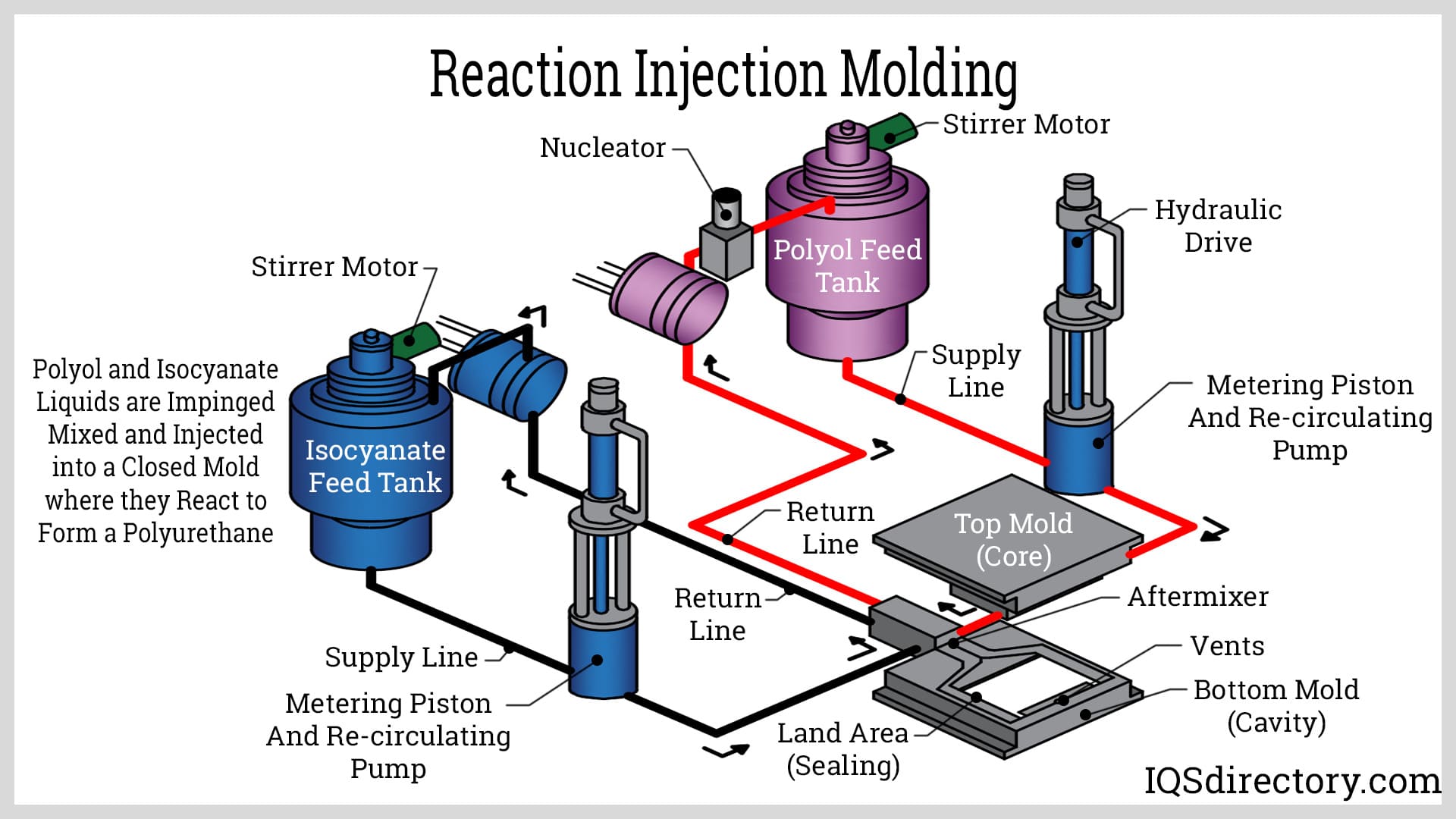

The plastic material that will be used for the case (usually polyethylene) is first melted down and then injected onto a core pin. As this core pin rotates over a molding station the material is inflated with air so that a hollow area is created in the middle. The plastic is then given time to cool. Once it has cooled down, the plastic is removed from the mold and it remains formed to the exact shape of the case mold. The same mold can be used over and over again to create a case with the exact same specifications.

Injection molding is an ideal manufacturing process for large volume runs in a major manufacturing facility where hundreds or even thousands of injection molded cases may be manufactured at the same time. This is because once the mold has been designed and the equipment has been programmed, the injection molding process itself is very quick and easy to repeat.

Injection molded cases are made in many different shapes and sizes depending on the types of objects that they are made to hold. They may be used for electronic devices, sound equipment, heavy tools, instruments or a wide array of other goods that a person would want to protect from damage. Most cases are built with clasps to keep them tightly sealed, and some even have a built-in key lock beside the carrying handle for added security.

If the case is designed to accommodate a very specific item, the mold may be setup in such a way that the hollow portion on the inside of the case is in the exact shape of that item. This way, when the item is placed inside it will not shift when the case is moved. Sometimes an inner foam lining is cut in the shape of the object and added to the case after it has been molded.

A high quality injection molded case has many advantages besides basic damage protection. These cases are waterproof, lightweight, immune to rust, impact resistant and scratch resistant. Specialized trades personnel can use these cases to carry their equipment without having to worry about it being damaged by an accident on a busy job site.

Injection molded cases are used in applications that range from military to engineering to healthcare and beyond. The durability of their structure and the infinite design possibilities that the molding process allows for makes them a great choice for almost any industry. A rugged design, cost-efficient means of production and high degree of customization make injection molded cases a highly sought after product around the world.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services