Rapid injection molding is the technique of creating prototype, bridging, and short production run injection molds in a shorter time and at a lower cost than full production molds. Injection molds for long manufacturing runs are often exceedingly expensive and time-consuming. Read More…

For 50 years, LTM Plastics has been a leading manufacturer of injection molded plastics. When working with LTM Plastics, our customers can be assured that they are getting high quality products at a competitive price. We pride ourselves on our team’s communication and collaboration with our customers to meet their needs.

If you are in need of injection molded plastic parts that are of consistent quality, look no further than MSI Mold! We have over 30 years of experience in design, production, and tooling of custom plastic parts.

Performance Engineered Products, Inc. is a dynamic and innovative company, and we pride ourselves on being at the forefront of the injection molded plastics industry. With a rich history dating back to 1981, we have consistently demonstrated our commitment to excellence in both products and services.

We may have started small, but today, we offer our products and services to companies around the world. We are dedicated to our customers, and our goal is to offer better service and pricing to any customer no matter the size.

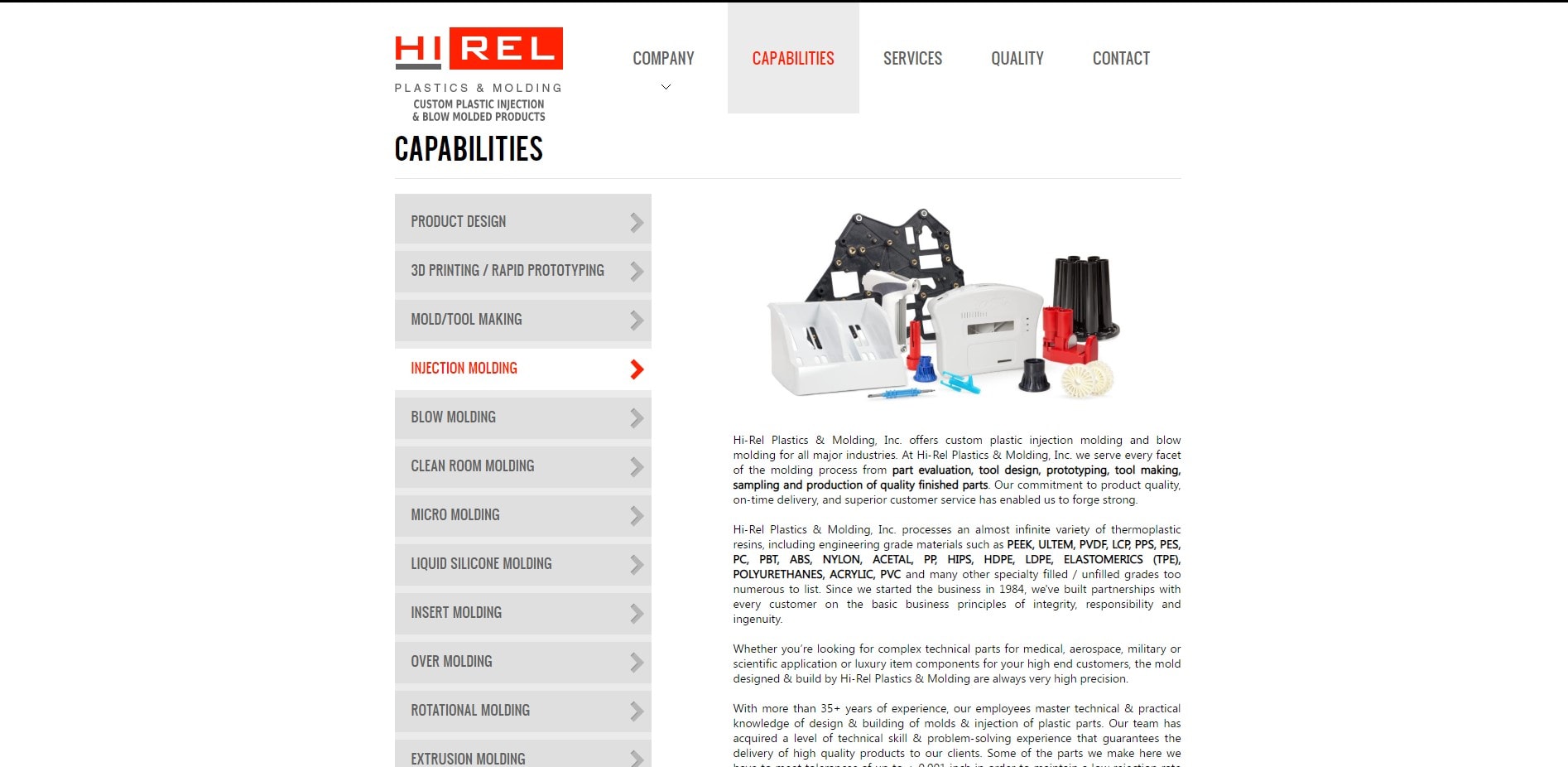

Hi-Rel Plastics & Molding, Inc. offers injection molding for a variety of industries. We can process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we provide superior customer service. Value-added services include label application, assembly services, and custom packaging and shipping. Our team has the knowledge and expertise to...

As one of the Midwest’s oldest plastic molders, Koller-Craft has craftsmanship built into its name. We take pride in our quality injection molding work. Large to small parts, short to long runs. Excelling at product design, prototyping, close tolerance molding, insert molding & secondary services.

A leader in the plastic processing industry for over 70 years, Aptyx provides a range of manufacturing services including injection, blow and dip molding, extrusion, and assembly. Within injection molding we are deeply experienced in complex processes such as over molding, two-shot molding and insert molding. With a focus on delivering high-quality product and exceptional customer service, you...

Valencia Plastics is your leading full-service injection molded plastics manufacturer. Our products are made with various materials, including urethane, polyurethane, nylon, acrylic, and polycarbonate. We offer a wide range of sizes from miniature items up to 7 lbs. large parts. We are ISO 9001:2015 compliant. Industries we serve include electrical, military, automotive, aerospace, and...

Abtec, Inc. is a manufacturer of injection molded thermoplastics for high-tech OEMs. Since 1981, we have provided quality injection molded plastics and engineering services to such industries as automotive, aerospace, dental, electronics, food handling, nuclear, reprographics and more. Our 21,000 square feet building operates 24-hours a day, 5 days a week. Contact us today!

You won’t find better quality injection molded plastics anywhere else in the industry. We have built ourselves up from a small manufacturing company to a large company with decades of experience.

More Rapid Injection Molding Companies

What is Rapid Injection Molding?

In cases where fast-tracking and early cost control are required, economic and quick rapid injection molding techniques can yield molds that are better suited to low-volume production runs. Engineers employ what's known as "rapid injection molding" when they need to make parts fast.

Rapid injection molded components are used to create prototype parts for design analysis. While valuable in that regard, quick injection molded components are often not used as a finished product; instead, they might be used as a bridge to production, producing parts for production while the genuine production mold is being created.

Rapid injection molding is thus more of a research and development process than a core production method.

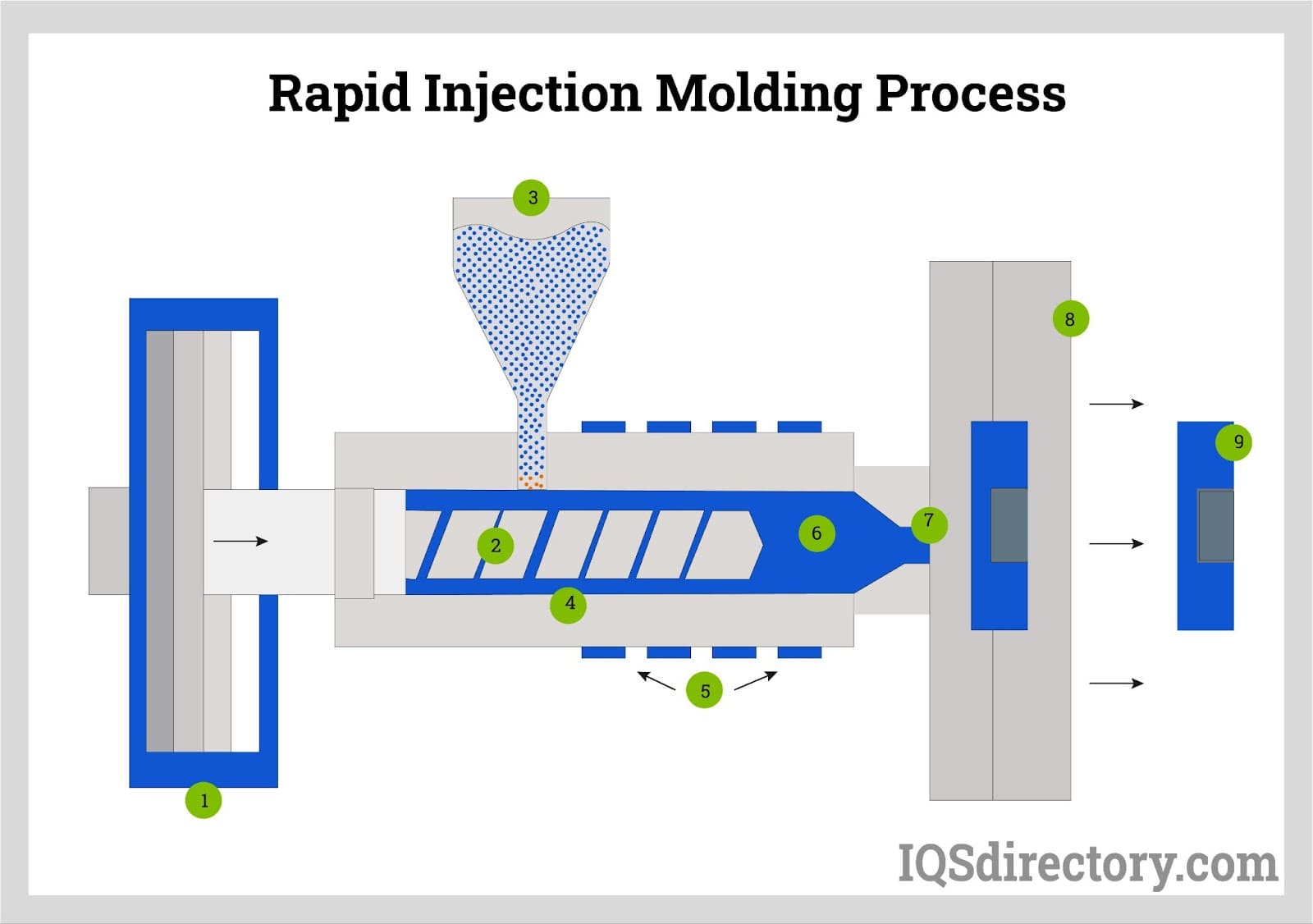

Rapid Injection Molding Process

The overall method of rapid injection molding is very similar to that of normal injection molding; it is merely a speedier approach to the process in order to have a prototype dispatched sooner.

The method still involves pumping molten plastic into a mold designed to fit the final product, then allowing it to cool, harden, and adopt the shape of the mold. Following the hardening and removal of the material from the mold, the product undergoes several secondary finishing operations to verify that all customer requirements are met.

Because of their versatility and numerous physical qualities, thermoplastics are among the most often used materials in injection molding. As a result, they can be used in a wide range of industrial applications.

As previously mentioned, the mold is designed with the ultimate product in mind, so it is critical that the customer receives a prototype as soon as possible to guarantee that the final product meets their expectations.

Considerations When Performing RIM

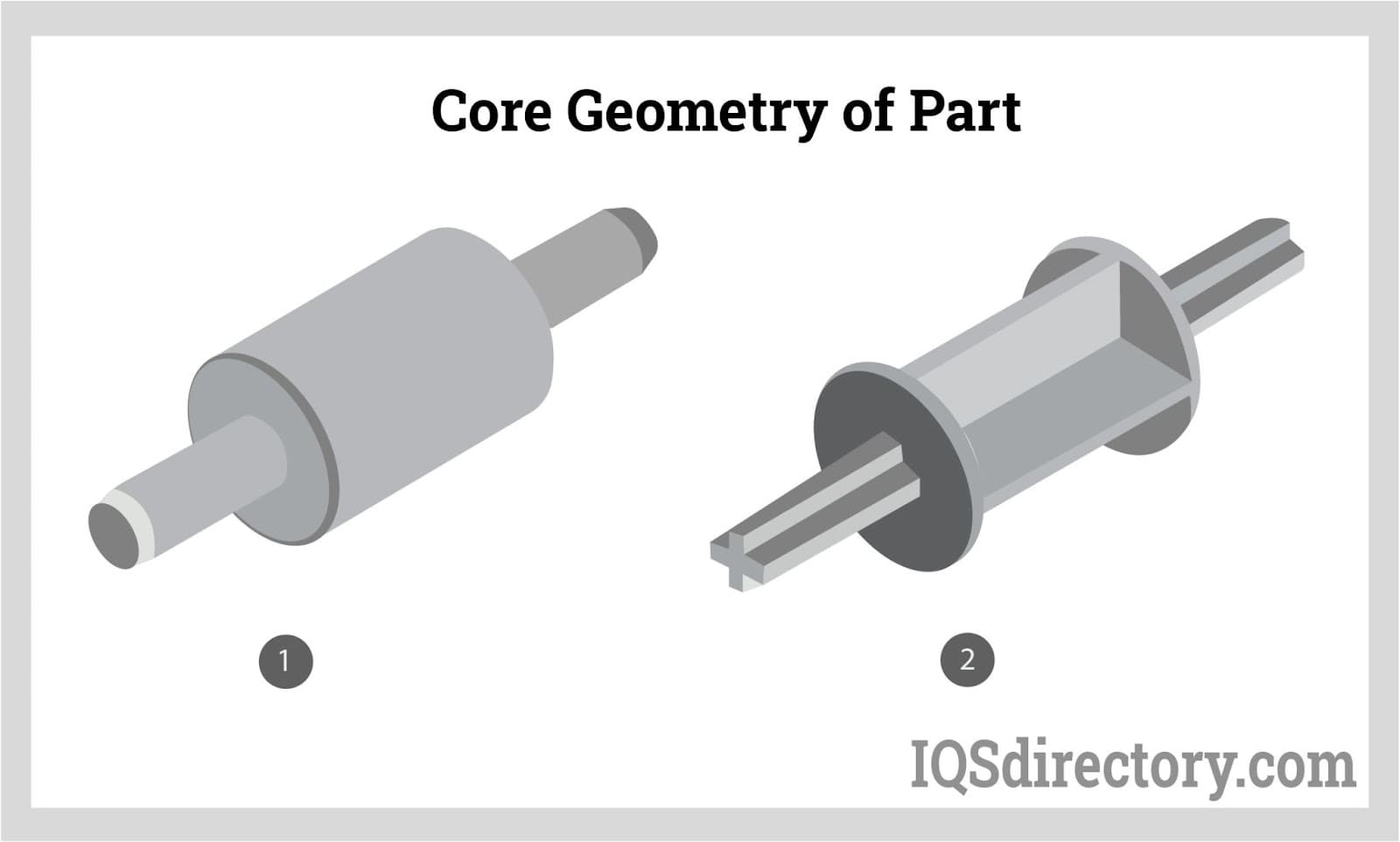

Core Geometry

Thick walls are removed by coring out portions. A well-molded item performs the same functions. Unnecessary thickness can change the proportions of a product, impair its strength, and need post-process machining.

Drafted Walls

As much as feasible, draft (slope the vertical walls) to make it easier to expel pieces without drag marks or ejector punch marks. Drafting allows designers to build deeper features when milling deep walls and avoids tool clatter and cosmetic faults. Use 1 degree of draft or more if space allows, and use 2 degrees or greater on core-cavity designs. A rough rule of thumb is one degree of draft for each of the first two inches of depth. From 2 to 4 inches in depth, either a 3-degree draft or a minimum thickness of 1/8 inch may be necessary.

Core-Cavity

Instead of ribs, utilize core-cavity while drafting. Rather than having walls with a thick base, it gives consistent wall thicknesses. It also enables machine shops to grind molds with a better surface polish and provide higher-quality products more quickly.

Side-Actions

On the outside of a part, side-actions create undercuts. The undercuts must be on the parting line or related to it. They must also be in the same plane as the parting line and perpendicular to the mold's opening direction.

Steel Core Pins

Steel core pins can be used to make these holes in the mold. Steel pins are robust enough to withstand the stress of ejection while also being smooth enough to release the part cleanly and without draft. There should be no cosmetic influence on the finished product; if there is, it will be hidden inside the hole.

Advantages of Rapid Injection Molding

Fast processing: Because prototype tooling produces rapid results, the time between development and production is kept to a minimum.

Advanced mold customization: This is possible because of the quick tooling process.

Proof of concept/testing: Rapid prototyping makes it easier to do real-world design testing and debugging. It also permits the manufacturing of new tooling that incorporates design modifications and upgrades in a timely and exact manner.

Faster time to market: Fast manufacturing and precise tooling contribute to production efficiency, allowing for a faster time to market than alternative approaches.

Competitive pricing: The quick tooling process' affordability significantly influences and benefits the clients' bottom line.

Choosing the Correct Rapid Injection Molding Company

To make sure you have the most constructive outcome when purchasing Rapid Injection Molding from a Rapid Injection Molding Company, it is important to compare at least 5 Companies using our Rapid Injection Molding directory. Each Rapid Injection Molding Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Rapid Injection Molding company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Rapid Injection Molding companies with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services